Welded Tube Assemblies

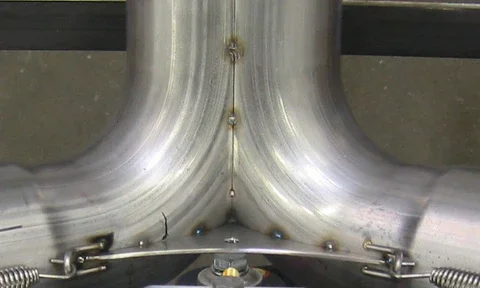

Precision Welded Tube Assemblies Built to Perform

We deliver production-ready welded tube assemblies with the precision, repeatability, and quality control OEMs demand. From simple joints to complex, multi-tube frames, we specialize in fabricating structural and functional parts that integrate seamlessly into your equipment and systems.

-

MIG Welding

Ideal for structural joints and high-throughput production of mild and stainless steel tube assemblies.

-

TIG Welding

Used for thinner-wall tubing, stainless steel, and parts requiring clean, precise welds with tight visual or mechanical specs.

-

Tack Welding

Efficient for high-volume joining of small tube components, especially in fixture-based applications.

-

Weld Fixture Design

Our tool room creates custom-built fixtures to ensure repeatability, alignment, and speed during the welding process—critical for multi-joint assemblies.

Welded Assembly Examples

We specialize in repeatable welded assemblies for OEMs across multiple industries, including:

Mounting brackets with welded tube arms

Tube frames and subframes for ag or utility equipment

Structural supports and handrails for power equipment

Engine mounts and exhaust brackets for powersports

Hydraulic tube assemblies integrated with fittings and flanges

From 50 pieces to 10,000+ piece production runs, we deliver consistent weld quality across all volumes.

material capabilities

We’re experienced in welding the full range of formable tubing materials, including:

Mild steel (ERW, DOM)

Stainless steel (304, 316)

Aluminum (select cases – inquire)

Chrome-moly (4130)

Cold-drawn and seamless tube

Round, square, and rectangular profiles